Everything is possible –

Screws as special and custom parts

Where standard screws reach their limits, bespoke screws are the ideal problem solver. Longer threads for deeper holes? Special drive forms for higher torques or automated assembly?

All special requests are possible with our service for special and custom parts.

Choose the screw drive and head shape, screw thread and screw tip to your precise requirements to create your bespoke screw. We provide you with a variety of options for choice. In this way, you get a precisely configured screw made of stainless steel. It goes without saying that we can deliver all special and custom parts in a stainless steel alloy of your choice. The high quality standards of our regular screws also apply to our special screws without restriction.

A first-sample test report on your special and custom parts can also be prepared on request.

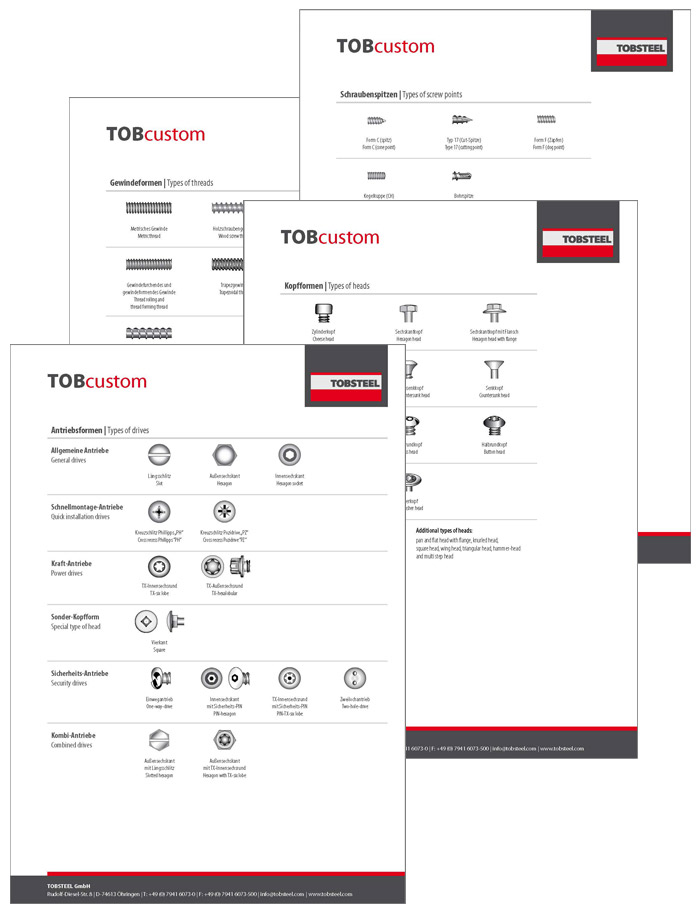

Simple selection in a modular system

Three methods exist for defining your dream screw. 2D drawings are highly suited as a template for production. These can be created using all popular CAD and drawing programs.

1. Based on a standard:

In the simplest case, you choose the ISO or DIN standard that you would want your screw to comply with, and then define your differing wishes. This may be a different screw head shape, for example, or a longer or shorter screw thread and a different shape for the screw tip. Whether you need a screw drive that is suited to automated assembly or a special material – no limits exist to the possibilities available to you for special and custom parts.

2. By modifying an existing product:

Frequently a conventional standard screw is almost perfect, but there is that little something missing. Be it a thread lock or a coating, a paint job or a head stamp. Our service implements the change to the screw or nut on your behalf, so the connecting part fulfils its task perfectly.

3. In free configuration:

Create your own personal screw freely with the components screw drive, screw head shape, screw thread and screw tip. You have the choice of several stainless steel alloys for the material. We have access to all relevant manufacturing processes including cold and hot forming, turning, milling, punching, laser cutting and grinding, etc. This allows us to create practically any special and custom part possible.

You can configure your screw

from these components:

The screw drive determines which tool is used to insert the screw. Conventional slotted screws and external hexagon drives are available in addition to cross recess screws such as PZ (Pozidrive) and PH (Phillips), as well as hexalobular drives such as TX (Torx) for fast automated assembly.

The screw head shape affects both the assembly options and also their effect in an assembled state. For example, countersunk heads are favoured for use as wood screws, because they are flush with the surface. Flat round heads take on a similar function for metals as they round off the screw point. The conventional external hexagon also takes over the function of the screw drive. Knurling and blade heads allow for tool-free insertion with low tightening torques.

The choice of the screw thread depends on the job the screw should fulfil. Whether wood thread, metric thread or tapping screw thread – each thread is adapted to its use.

The screw tip facilitates inserting and screwing in the screw. With the right tip, a wood screw can penetrate the material easily, while a metal screw can be screwed in easily without jamming.

Additional features sometimes make a screw even more perfect. Milling ribs on the countersunk head to easily screw in wood screws flush to the surface, for example. Or a head stamp designed for your company.

Do you have any questions?

We make (almost) anything possible for you!

Our sales team will be more than glad to help you and inform you about the many options we have available for special and custom parts.

Our Sales Team will be more than happy to help you further:

T: +49 7941 6073-0 sales@tobsteel.com